A comparative analysis: Turbine spirometry vs. ultrasound spirometry

Lung diseases are becoming more prevalent and burdensome on a global scale. As lung diseases become more widespread, the rate at which they are diagnosed should also be improved worldwide.

The diagnosis of chronic obstructive pulmonary disease (COPD), for example, requires spirometric assessment. Other conditions, such as cystic fibrosis1 and pulmonary fibrosis, rely on spirometry for clinical monitoring. Considering this, spirometry is also the tool used to measure clinical outcomes necessary for the evaluation and approval of medications. To ensure objective analysis, low variability and high repeatability of the measurements are a key factor.

There are three main operation principles that are used for spirometers: Differential pressure, turbine, and ultrasound. There are substantial differences between these three operation principles. In this blog, we focus on comparing spirometers based on turbines and based on ultrasound.

Turbine spirometers #

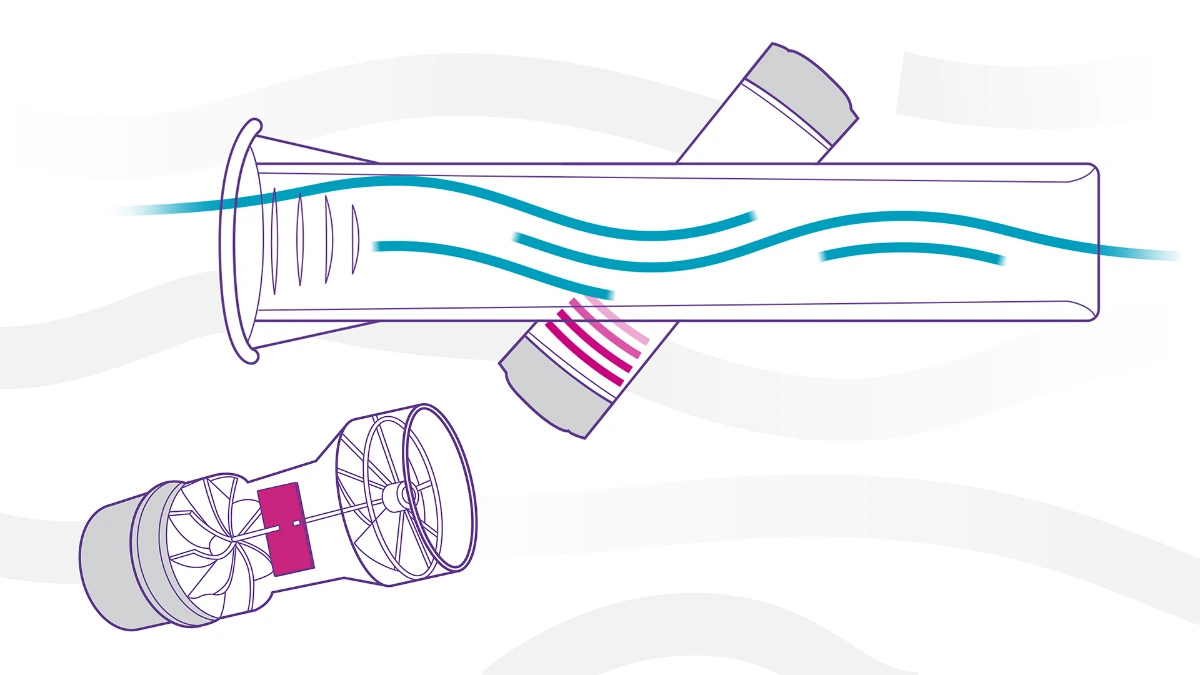

Turbine spirometers are based on a lightweight mechanical vane mounted within the airflow path. Additional mechanical elements in the flow path condition the flow in such a way that the vane is put into rotation when air moves through the spirometer. The rotation of the vane is optically measured. The rotation speed is then converted into an airflow speed measurement.

Figure 1: Schematic view of turbine spirometer (https://www.pftforum.com/blog/turbine-spirometers/)

Advantages & disadvantages: Turbine sensors #

The main advantages of turbine flow sensors are:

- Reusable turbine.

- Lightweight sensor.

- Low cost due to simple technology.

The main disadvantages are:

- Fragile mechanical parts in the flow path are prone to damage.

- Damage and/or blockages by small hairs, dust particles etc. may change the characteristics of the device.

- The sampling rate of the sensor is dependent on the airflow. For low flows the sampling rate might fall below the ATS/ERS recommended sampling rate of 100 Hz.

- Low flows and rapidly accelerating flows can only be measured inaccurately.

- Flow measurement is influenced by changes in gas composition, temperature and/or humidity.

Ultrasound spirometers #

Flow measurement based on ultrasound has been used in large pipes for a very long time. However, ultrasound spirometry has only been commercially introduced around the year 2000 by ndd Medical Technologies.

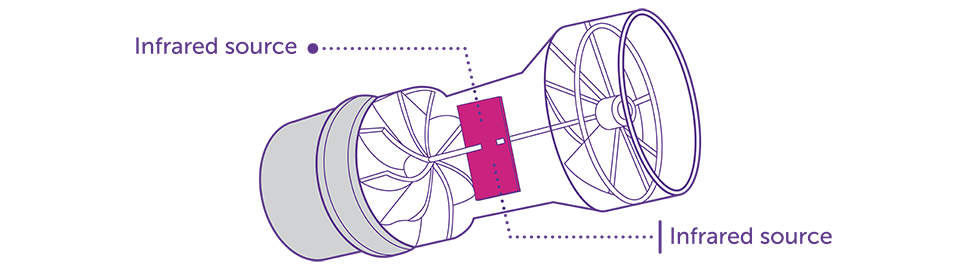

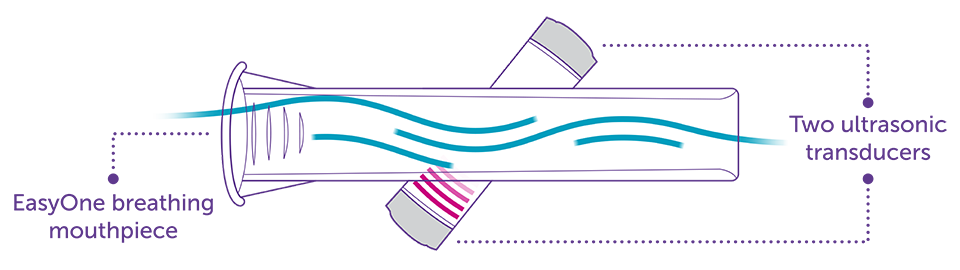

Ultrasonic flow sensors measure the airflow velocity using ultrasonic signals transmitted within the flow tube. For that purpose, two ultrasonic transducers are mounted on opposite sides of the flow tube (see figure 2 below). If air flows from left to right, an ultrasonic pulse that travels from the lower transducer to the upper requires less time than a pulse traveling in the opposite direction. This is the case since the moving air speeds up or slows down the pulses traveling between the transducers. Ultrasonic spirometers have a completely open flow path without any mechanical parts in the tube.

Figure 2: A diagram of ndd Medical Technologies’ EasyOne device with TrueFlow and TrueCheck technology (https://nddmed.com/pulmonary-function-test-solutions/ndd-pft-technology)

Advantages: Ultrasound flow sensor #

The main advantages of ndd’s ultrasonic flow sensors are:

- Open flow tube, i.e. no sensor element within the flow tube.

- Flow measurement is not influenced by gas composition, humidity and temperature.

- Sampling rate is constant and not dependent on airflow.

- Exchangeable flow tube eliminating the risk of cross-contamination.

- Proven long-term stability2 and therefore calibration-free.3

- High degree of flow and volume accuracy over the entire flow range.3

Conclusion #

All of ndd’s pulmonary function testing devices utilize ultrasonic flow sensor technology. The measurement is performed using a custom integrated circuit developed by ndd. The circuit has been optimized carefully, eliminating the influence of gas composition, pressure, temperature, and humidity on the performance of the device.These optimizations make ndd devices superior to other implementations of ultrasonic flow sensors. This is a key reason why our devices have been utilized in multiple, high-visibility clinical research studies, including COPDGene, Multicenter AIDS Cohort Study (MACS), and the BOLD and PLATINO studies. This wouldn’t be possible without the unique features of ultrasonic technology developed by ndd.

The biggest advantages of ndd’s ultrasonic flow sensor technology are its accurate performance at low flows, its high durability combined with low measurement variability, and high repeatability. These advantages cannot be matched by the performance of turbine spirometers.

The performance of spirometers in the low flow region, a clear disadvantage of turbine spirometers is a key element when measuring patients with COPD. As these patients perform long exhalations at low flow levels, measuring these patients with high accuracy is key for correct diagnosis.

Utilize our About page and Our Values page to learn more about our history, our mission and focus and how our technology plays a central role in all of it.

de Aquino CSB, Rodrigues JC, da Silva-Filho LVRF. Routine spirometry in cystic fibrosis patients: impact on pulmonary exacerbation diagnosis and FEV1 decline. J Bras Pneumol. 48(3):e20210237. doi:10.36416/1806-3756/e20210237 ↩︎

Pérez-Padilla R, Vázquez-García JC, Márquez MN, et al. The long-term stability of portable spirometers used in a multinational study of the prevalence of chronic obstructive pulmonary disease. Respir Care. 2006;51(10):1167-1171. ↩︎

Skloot GS, Edwards NT, Enright PL. Four-year calibration stability of the EasyOne portable spirometer. Respir Care. 2010;55(7):873-877. ↩︎ ↩︎

Written by

Tré LaRosa

Tré LaRosa is a consultant, scientist, and writer in the Washington, DC area with extensive experience working in research (basic, translational, and clinical) and on patient-reported outcomes. He has also written extensively on neuroscience, pulmonology, and respiratory conditions, including from the patient perspective. He enjoys learning, reading, writing, spending time outdoors, and telling everybody about his mini golden retriever, Duncan.